- The Ford Model T was named the vehicle of the century.

- Ford Motor Company of South Africa was established in 1923.

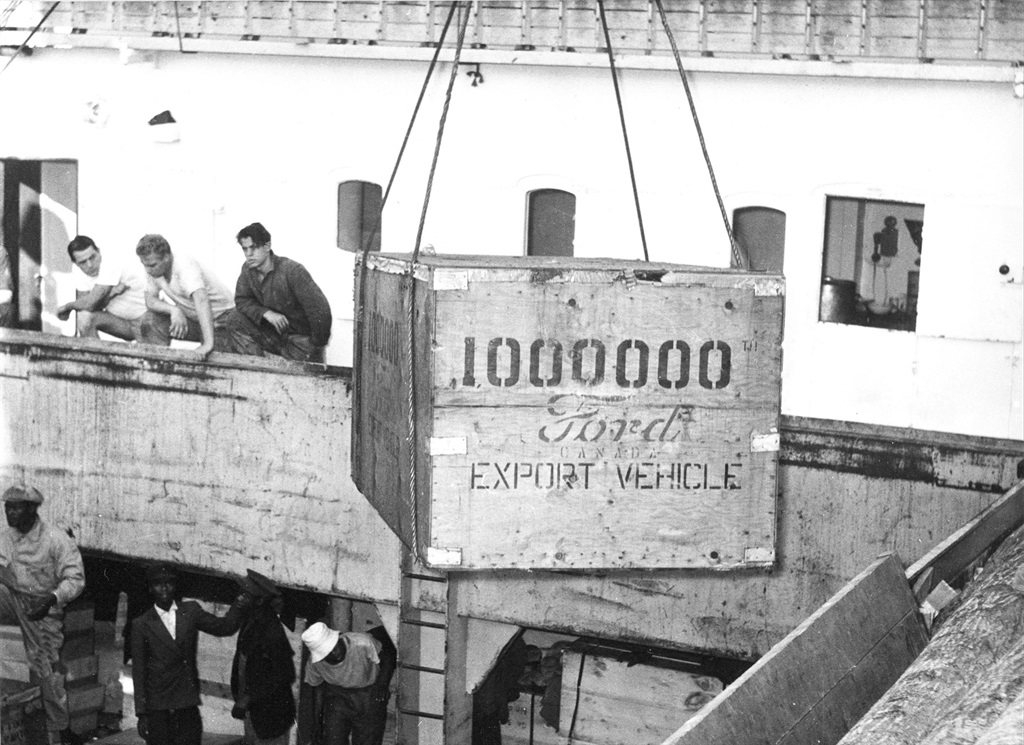

- In 1976, Ford Motor Company of South Africa produced its one-millionth vehicle.

- For more lifestyle news, go to theNews24 Life front page.

In the modern world, we take for granted the conveniences that have become integral to our daily lives: computers, high-speed internet, smartphones, air travel, and automobiles. These innovations have dramatically changed our world in just a century. Among the companies at the forefront of this transformation, Ford stands out, particularly in South Africa, where it has played an essential role for a century!

Ford's beginnings

In 1903, the same year that saw the Wright brothers' historic flight, Henry Ford founded the Ford Motor Company alongside a group of investors. Armed with a modest $28 000, the company embarked on its remarkable journey.

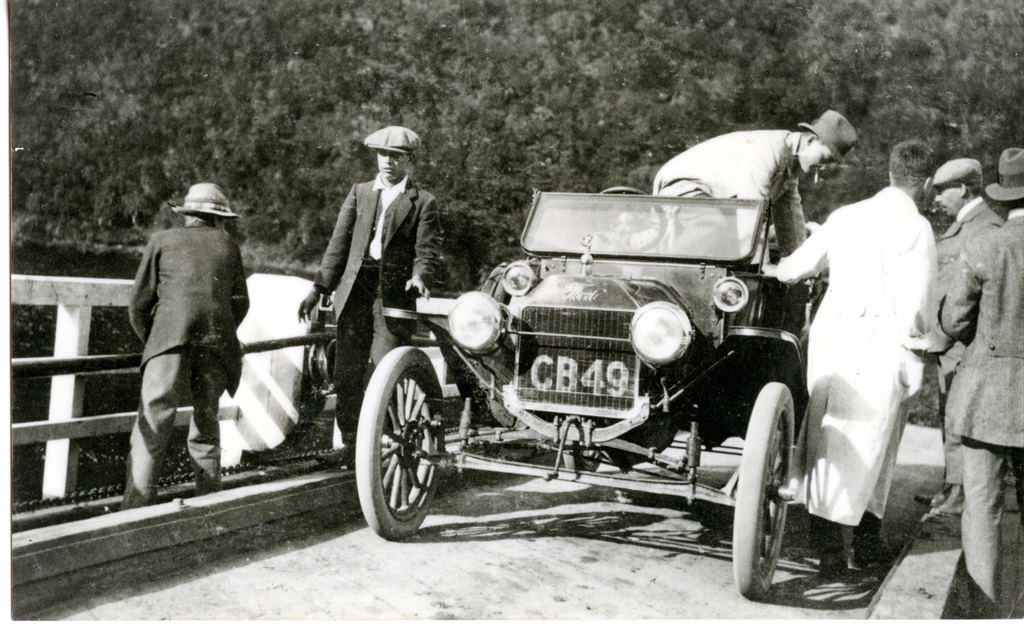

Ford recognised South Africa's strategic importance, appointing local agents in Port Elizabeth to distribute and sell Ford cars.

PHOTOS | Celebrating Ford's centenary in SA: What it's like driving a 108-year-old Model T

The Model T revolution

While early Ford models set the wheels of progress in motion, the Model T, launched in 1908, truly catapulted the company to meteoric success. By the end of the 1920s, Ford's Detroit plant produced a remarkable 9 000 vehicles daily, thanks to the introduction of the pioneering moving assembly line in 1913, reducing production time from 12 hours to just 90 minutes.

To meet global demand for the Model T, Ford expanded to Canada, supplying vehicles to the British Commonwealth markets, including South Africa. The Model T quickly became South Africa's favourite car, leading to the decision to commence local vehicle assembly.

Ford's arrival in South Africa

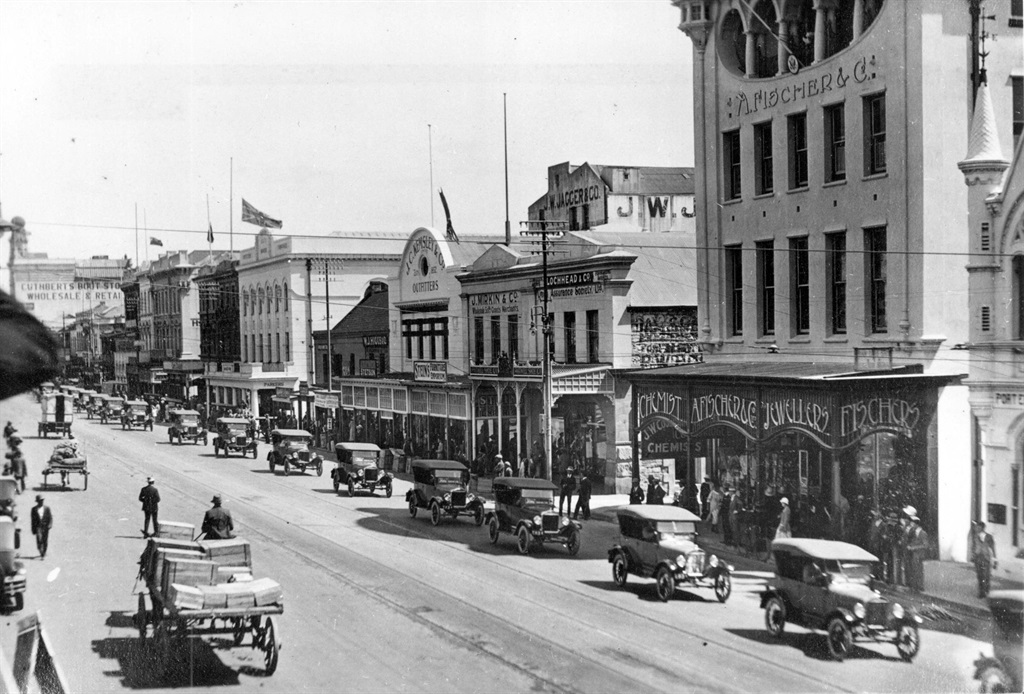

In November 1923, Ford Motor Company of South Africa was established in Port Elizabeth; the company converted an old wool store into its 16th assembly plant outside of the United States. Local assembly began with Model T kits imported from Canada, making Ford the first global vehicle manufacturer to operate in South Africa.

Assembly operations started in January 1924, producing 10 cars per day, with the first locally made models hitting the market in March. Within the first year, 1 446 vehicles were built, emphasising affordability as a key to Ford's success.

ALSO READ | How a letter from a farmer's wife inspired Ford to build the Ranger bakkie

Early dominance and expansion

In those formative years, Ford dominated the South African market. By the end of 1925, government records showed a staggering 18 118 licensed Fords in the country, almost three times the count of its closest competitor.

By 1926, Ford introduced a variety of colours beyond traditional black, offering options like "deep mole" and "dark green". In the same year, the plant produced a combined total of 2 069 cars and 1 093 trucks.

The production of the iconic Model T culminated in 1927, with an astonishing 15 million units manufactured worldwide. This iconic car was later crowned the Car of the Century in 1999, reflecting its pivotal role in making automobiles accessible to the masses.

Facility growth

In October 1930, Ford Motor Company of South Africa relocated to a new factory in Harrower Road, Port Elizabeth, expanding its facilities to 7,032 square metres at a cost of R1 110 503 at the time. The factory initially produced the Model A at a rate of 90 vehicles per day.

Formation of Naamsa

In September 1935, the National Association of Automobile Manufacturers of South Africa (Naamsa) was established, with Ford as a founding member. This organisation remains a cornerstone of the industry, nearly nine decades later.

World War II contributions

During World War II, the Ford plant played a significant role, producing almost 60 000 vehicles between 1939 and 1945, with 36 339 cars going to the Union Defence Force. Ford also repaired wings for Anson training aircraft for the South African Air Force. Post-war production resumed in June 1946.

Expansion in 1947

By 1947, Ford was ready for another expansion, constructing a new plant in the Neave Industrial Township, PE. This R2-million facility officially opened on 1 October, 1948, becoming the largest plant under one roof in South Africa, with an astonishing 354-metre window.

Innovations and local success

In 1954, Ford integrated a modern administration block into the plant for R1 million. The Neave plant produced a range of memorable vehicles, including the Fairlane, Zephyr, Zodiac, Anglia, Prefect, Consul, Escort, Granada, and the legendary two-door Capri.

It also served as the assembly point for Ford's Thames and Louisville trucks and Fordson Major diesel tractors for local consumption and export across Sub-Saharan Africa.

Remarkably, all three of these early Ford plants still stand today, repurposed and sold to new owners over the years.

Investments in the 1960s

During the 1960s, Ford invested substantially in the domestic automotive sector, announcing a R4-million expansion initiative in 1962. This comprehensive endeavour included constructing a parts-and-accessories warehouse in Struandale, extending the Neave plant to accommodate an engine assembly line, and developing a new test track.

Struandale Engine Plant

In October 1963, Ford revealed a groundbreaking R8-million investment.

Henry Ford II officially inaugurated The Struandale Engine Plant in May 1964, marking a historic milestone as the first automotive company in South Africa to manufacture engines for passenger cars and trucks locally. This state-of-the-art facility employed 300 skilled workers and initiated production with the renowned 3.0-litre Essex V6 engine, which would become synonymous with high-performance Ford vehicles in the following decades.

Testing and development facilities

In 1966, Ford acquired a sprawling 3 400-acre site known as the Rietkuil farm, adjacent to the St Alban's Airport west of Port Elizabeth. This created a cutting-edge proving ground with four test tracks of varying surfaces. A product development and engineering facility established in 1968 became the breeding ground for innovative developments unique to South Africa. These included various iterations of the Cortina bakkie and the introduction of the Bantam bakkie in 1983, the first vehicle to win the prestigious Shell Design Award.

Expanding Cortina production

Ford invested R9.25 million in constructing the Struandale Assembly Plant in the 1970s. This specialised plant, dedicated to Cortina production, began operations in 1973, with an initial capacity of 110 units per day.

Production of the Cortina continued until 1983, with over 303 000 units sold in South Africa. Ford also operated a truck assembly plant in Deal Party Estate, conducting the final assembly of the rugged D-Series and F-Series trucks.

Milestone achievements

In 1976, Ford Motor Company of South Africa produced its one-millionth vehicle, reinforcing its status as a major player in the local automotive industry. Port Elizabeth, a vehicle manufacturing hub since the 1920s, earned the nickname "Detroit of South Africa".

Political changes and local innovation

The political turmoil of the 1980s prompted Ford to enter negotiations with Amcar and Anglo American. This led to the creation of the South African Motor Corporation (Samcor) in 1985, assuming control of Ford's local operations. Ford's 40% ownership stake eventually transitioned to a trust, which allocated shares to its black employees, marking an unprecedented move for the time.

Transition and innovation

Due to strict sanctions and isolation during the apartheid era, Ford's local engineers had to devise innovative solutions to maintain the competitiveness of their vehicles. This led to the creation of legendary cars like the Cortina XR6, Sierra XR6, and Sierra XR8, powered by a Mustang-derived 5.0L V8 engine.

Return to South Africa

In 1993, the production of the two-millionth vehicle signalled Ford's return to South Africa. In 1994, Ford acquired a 45% equity stake in Samcor from Anglo-American, demonstrating confidence in the country's transition to democracy.

The Ford Fiesta comes home

In 1997, production of the Ford Fiesta began at the Silverton Assembly Plant, and it quickly earned the prestigious title of South African Car of the Year.

Full ownership and Ranger's introduction

In 2000, Ford acquired 100% equity in Samcor, establishing the Ford Motor Company of Southern Africa (FMCSA). That same year, the first-generation Ranger was unveiled, replacing the Courier and reaffirming Ford's position in the light commercial vehicle segment.

Ranger's global success

Between 2000 and 2011, 105 950 Rangers were sold in South Africa. Ford streamlined its manufacturing portfolio, focusing solely on the Ranger platform.

Major investment in the Ranger

In 2010, Ford confirmed a massive R3.4-billion investment in South Africa, doubling its local manufacturing capacity to 110 000 vehicles per year. The new Ranger set new design, comfort, luxury, performance, and safety standards.

Sustainability initiatives and engine innovation

In 2022, the Silverton Assembly Plant launched a pioneering solar-energy project. Solar photovoltaic carports for 3 610 vehicles were installed, generating approximately 35% of the facility's electricity needs. Additionally, a further R600 million was invested in the Struandale Engine Plant to introduce a third diesel engine programme, featuring the new 3.0L V6 engine, which became the flagship powerplant for the locally produced Ranger line-up.

Future commitment

Ford's journey in South Africa is a testament to innovation, adaptation, and resilience in facing challenges. It's a story of not just building cars but also building communities, creating opportunities and leaving a lasting impact on the country's automotive landscape.

As Ford celebrates its centenary in South Africa, it looks forward to the next century of shaping mobility, enriching lives, and driving progress.

Publications

Publications

Partners

Partners